Custom immersed tube tunnel Manufacturers and Suppliers

- Introduction: Why a Custom Immersed Tube Tunnel Can Elevate Your Attraction

- What Is an Immersed Tube Tunnel in the Attractions Context?

- Clarifying the term: civil engineering vs. attraction use

- Why Attractions Choose Custom Immersed Tube Tunnel Solutions

- Business and guest experience drivers

- Key Design and Manufacturing Considerations

- Structure, materials, and guest sightlines

- Materials and Fabrication Options

- Common materials and why they matter

- Installation, Site Preparation, and Logistics

- From factory to site: minimizing downtime

- Safety, Codes, and Compliance

- Regulatory and operational requirements

- Cost Drivers and Typical Timelines

- What affects price and lead time for a custom immersed tube tunnel?

- Comparison: Civil Immersed Tube Tunnel vs. Attraction Immersed Tube Tunnel

- How to Evaluate Custom Immersed Tube Tunnel Manufacturers and Suppliers

- Checklist for procurement teams

- Why Choose JAMMA Amusement as Your Supplier for Immersive Tunnel Attractions

- Capabilities, team, and value proposition

- Case Approach: Typical Project Workflow with a Supplier

- From briefing to handover

- Maintenance and Lifecycle Considerations

- Protecting investment and guest safety

- Conclusion: How to Move Forward with Your Immersed Tube Tunnel Project

- Next steps for procurement and design teams

- Frequently Asked Questions

Introduction: Why a Custom Immersed Tube Tunnel Can Elevate Your Attraction

Overview: In the attractions and aquarium market, a well-designed immersed tube tunnel is more than a passage — it’s an immersive storytelling device that increases dwell time, ticket value, and repeat visitation. Operators searching for custom immersed tube tunnel manufacturers and suppliers are typically project owners, designers, or procurement teams aiming to deliver a high-impact, reliable guest experience. This article explains practical options, procurement questions, and how to choose a partner who can deliver design, manufacturing, and installation for immersive tunnels suitable for parks, aquariums, and experiential centers.

What Is an Immersed Tube Tunnel in the Attractions Context?

Clarifying the term: civil engineering vs. attraction use

The term immersed tube tunnel is commonly used in civil engineering to describe large submerged tunnels built by floating, sinking, and joining prefabricated segments. In the attractions and aquarium sectors, however, immersed tube tunnel generally refers to immersive, prefabricated tunnel structures (often transparent or translucent) that are integrated into water habitats or themed pathways. These attraction-focused immersed tube tunnel installations prioritize guest sightlines, life-support systems for animals (in aquariums), audio-visual integration, and ease of manufacture and installation more than large-scale marine engineering.

Why Attractions Choose Custom Immersed Tube Tunnel Solutions

Business and guest experience drivers

Operators choose custom immersed tube tunnel suppliers to achieve: unique thematic design, high-quality acrylic or laminated glazing for underwater viewing, integrated AV and lighting for storytelling, and prefabricated modular systems that reduce on-site disruption. The keyword immersed tube tunnel signals strong from buyers who want a purpose-built attraction component rather than an off-the-shelf prop.

Key Design and Manufacturing Considerations

Structure, materials, and guest sightlines

Critical engineering and creative decisions include tunnel diameter, glazing type (acrylic vs laminated glass), structural framing (stainless steel or engineered composites), and internal finishes. For aquatic installations, designers must coordinate with life-support systems, animal welfare teams, and hydrodynamic modeling to ensure animal health and clear viewing. Manufacturers with multidisciplinary teams (marine engineers, AV integrators, fabricators) provide better outcomes for custom immersed tube tunnel projects.

Materials and Fabrication Options

Common materials and why they matter

Typical materials used in attraction-style immersed tube tunnels include cast or bonded acrylic panels for clarity and strength, marine-grade stainless steel (316) for internal frames, epoxy-bonded seals, and marine-grade composite backing. Acoustic treatments, anti-glare coatings, and scratch-resistant surfaces are frequently applied. Choosing the right materials affects maintenance cycles, warranty, and guest safety.

Installation, Site Preparation, and Logistics

From factory to site: minimizing downtime

Prefabrication shortens site works: modular tunnel segments are manufactured off-site, tested (waterproofing, structural load, AV), then transported and assembled on-site. Key logistics include transport route surveys, crane capacity, wet-fit/in-situ sealing protocols for aquariums, and coordination with mechanical systems. Reliable manufacturers provide installation teams, technical manuals, and on-site supervision to reduce risk and schedule overruns.

Safety, Codes, and Compliance

Regulatory and operational requirements

Immersed tube tunnel attractions must meet local building codes, ADA/accessible design requirements, fire and egress standards, and aquarium-specific health standards where applicable. Manufacturers and suppliers should provide engineered drawings stamped by licensed structural engineers and comply with local permitting processes. Regular maintenance plans and inspection schedules are essential for long-term safety and performance.

Cost Drivers and Typical Timelines

What affects price and lead time for a custom immersed tube tunnel?

Major cost drivers include tunnel length and diameter, glazing type and thickness, complexity of AV/interactive systems, life-support integration, and transport/installation logistics. Lead time for a fully custom tunnel (concept to install) often ranges from 6 to 18 months depending on complexity and permitting; modular or repeatable designs can shorten delivery time. Because site and regulatory variables vary widely, suppliers should provide phased budgets and milestone-based schedules.

Comparison: Civil Immersed Tube Tunnel vs. Attraction Immersed Tube Tunnel

Understanding the difference helps procurement teams select appropriate manufacturers and avoid misaligned proposals.

| Feature | Civil Immersed Tube Tunnel | Attraction Immersed Tube Tunnel |

|---|---|---|

| Primary purpose | Transport infrastructure (road/rail) under water | Guest viewing, themed walkthroughs, aquarium habitats |

| Scale | Very large (multi-lane, long spans) | Small to medium (meters to tens of meters) |

| Typical materials | Reinforced concrete segments, heavy-duty seals | Acrylic glazing, stainless steel frames, composites |

| Regulatory focus | Major civil engineering codes, marine permits | Building codes, aquarium health, life-safety standards |

| Manufacturer profile | Large marine/structural engineering firms | Specialist attraction fabricators, AV integrators |

How to Evaluate Custom Immersed Tube Tunnel Manufacturers and Suppliers

Checklist for procurement teams

Ask suppliers these critical questions before shortlisting:

- Do you have experience with aquarium or underwater-viewing tunnel projects? (Request references and photos.)

- Can you provide engineered drawings stamped by licensed engineers for my jurisdiction?

- What materials and glazing systems do you recommend and why?

- Do you offer integrated AV, lighting, and interactive systems? Can you demo these systems?

- What are your warranty terms and maintenance plans for glazing and seals?

- What is your approach to on-site installation and coordination with MEP and life-support teams?

- Can you provide a phased budget and timeline with milestone payments?

Why Choose JAMMA Amusement as Your Supplier for Immersive Tunnel Attractions

Capabilities, team, and value proposition

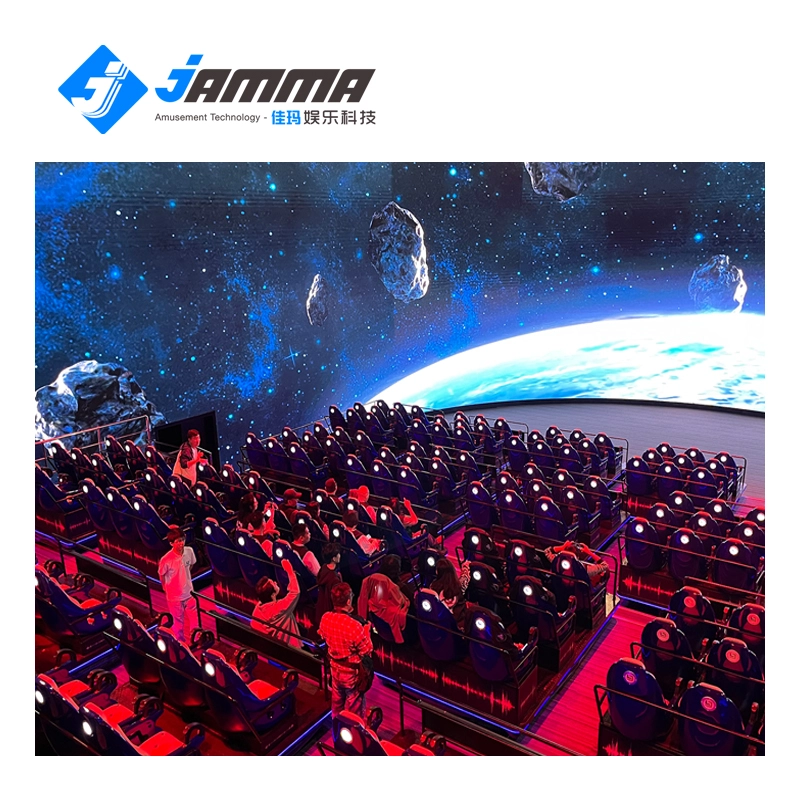

JAMMA Amusement, established in Guangzhou in 2009 with 15 years of experience in the amusement industry, focuses on high-value, one-stop solutions for amusement projects. While JAMMA does not build civil-scale immersed tubes, our strengths include designing and manufacturing immersive tunnel elements, VR/AR integration, interactive projection, and 5D cinema experiences that pair seamlessly with tunnel installations. Our international sales team understands venue needs and provides professional solutions; our technical, manufacturing, and after-sales teams provide installation guidance and ongoing support. JAMMA’s approach suits operators seeking turnkey immersive attractions featuring integrated audio-visual storytelling, high-quality glazing systems, and modular fabrication for efficient on-site assembly.

Case Approach: Typical Project Workflow with a Supplier

From briefing to handover

A reliable project workflow typically follows: (1) discovery and feasibility — assess site, guest flow, and regulatory needs; (2) concept design — visual and technical concepts with budget ranges; (3) detailed engineering — materials, structural, and AV integration; (4) factory fabrication and quality testing (water- and load-testing for aquarium tunnels); (5) logistics planning and on-site installation; (6) commissioning, staff training, and maintenance handover. Insist on clear deliverables and acceptance criteria at each phase.

Maintenance and Lifecycle Considerations

Protecting investment and guest safety

Long-term performance depends on routine inspections for glazing scratches, seal integrity, and structural fastenings. For aquarium tunnels, water chemistry can accelerate wear on seals and coatings, so documented maintenance schedules and accessible replacement panels minimize downtime. Suppliers should offer spare parts packages and remote or on-site technical service agreements.

Conclusion: How to Move Forward with Your Immersed Tube Tunnel Project

Next steps for procurement and design teams

If your project goal is to add a visually striking, durable immersed tube tunnel to your attraction or aquarium, begin with a concise brief that describes: tunnel purpose, desired guest experience, length/diameter targets, budget range, and site constraints. Shortlist suppliers with relevant aquarium or attraction tunnel experience, request engineered references, and evaluate turnkey capability for AV and life-support integration. JAMMA Amusement’s experience in immersive attractions makes us a practical partner for concept-to-installation delivery on immersive tunnel elements and integrated experiences.

Contact JAMMA Amusement: Visit https://www.jammapark.com/ to learn more about our immersive attraction solutions, or contact our international sales team for a consultation and preliminary proposal.

Frequently Asked Questions

No H-tags here — answers are separated by newlines as requested.

What is the difference between a civil immersed tube tunnel and an attraction immersed tube tunnel?An attraction immersed tube tunnel is a prefabricated, smaller-scale structure designed for guest viewing and theme experiences, typically using acrylic glazing and stainless-steel framing; a civil immersed tube tunnel is a large engineered marine structure for road or rail transport made from reinforced concrete segments.

How long does it take to deliver a custom immersed tube tunnel attraction?Typical timelines from concept to installation range from 6 to 18 months depending on complexity, permitting, and integration with life-support or AV systems. Modular, repeatable designs can shorten lead time.

What are the most durable glazing materials for underwater viewing tunnels?Cast or bondable acrylic is commonly used due to excellent optical clarity, impact resistance, and relative ease of fabrication compared to laminated glass for curved applications.

How do I evaluate the right manufacturer for my project?Request references for similar projects, ask for engineered drawings and test reports, confirm on-site installation capabilities, verify warranty and maintenance support, and ensure they can integrate AV and life-support systems if needed.

Are maintenance and spare parts typically included?Many suppliers offer maintenance packages and spare parts as optional or included items in a turnkey contract; ensure these are defined in the proposal to avoid surprises.

Can immersive tunnels be retrofitted into existing aquariums or attractions?Yes — retrofits are common, but complexity varies. A site survey and structural assessment are required to confirm load paths, access for installation, and compatibility with existing water treatment systems.

Sources:

- Themed Entertainment Association (TEA) / AECOM Global Attractions Attendance Report

- World Association of Zoos and Aquariums (WAZA) publications on aquarium trends and animal welfare

- PIANC (Professional Association for Waterborne Transport Infrastructure) guidelines and technical reports

- Federal Highway Administration (FHWA) and international tunnelling literature on immersed tube tunnel construction practices

- Industry fabrication standards for acrylic glazing and marine-grade stainless steel (manufacturer technical datasheets and engineering handbooks)

Custom high quality interactive dance floor led Manufacturers and Suppliers

How to Choose the 4d theatre manufacturer and supplier ?

What are the different types of smart interactive table?

OEM/ODM virtual boxing simulator Manufacturers and Suppliers

Product details

How many players can play soccer at the same time?

Up to 4 players can play at the same time, you need to add more soccer balls.

Can I customize the number of seats of 5D cinema?

Yes, we generally have options for six, nine, eighteen, twenty-four, and thirty-six seats, and the quantity of seats also can be customized.

Standard and other

What is the delivery time?

Usually the production period of our products is 20 to 25 days, it will be a little different according to the quantity of products you order. All products need to go through our strict quality inspection before shipment. After they are tested, we will ship them to you at the first time. For products in stock, we usually ship within 3 days.

Do you offer a customized service?

We can provide logo customization service for all of our products. For certain products, we can also support customization of sizes and game content. If you have any product customization requirements, please contact us and we will confirm the details with you.

How will it be transported?

For large items, we usually use sea freight, while for small items, we use air freight or services like DHL, FedEx, or UPS. We can also accommodate specific shipping methods based on your requirements.

Hottest activated LED dance grid tiles floor touch games

Super Grid is an immersive sports game that combines sports and technology. It integrates interactive LED lights and sensors through innovative software design, creating a fun gaming experience.

Top Indoor Tennis Racketball Training Simulator Dual Player Games

Interactive somatosensory fitness game

Combine traditional tennis sports with advanced 3D digital technology to bring customers an immersive tennis training experience

COMBINE TRADITIONAL TENNIS SPORTS WITH ADVANCED 3D DIGITAL TECHNOLOGY TO BRING CUSTOMERS AN IMMERSIVE TENNIS TRAINING EXPERIENCE INDOOR AND TENNIS EXPERIENCE HALL

Super Grid Interactive LED Floor Activate Game Team Play

Super Grid is an immersive sports game that combines sports and technology. It integrates interactive LED lights and sensors through innovative software design, creating a fun gaming experience.

Immersive 5D/7D/9D cinema dynamic visual experience room

Compared with other types of theaters, 5D/7D/9D cinema have high technical content, prominent themes, and have a strong impact on the characteristics of the picture. With the increasing demand in the entertainment market and the continuous development of video entertainment technology, in the past, audiences would experience vibration, drop, rain, scratches and other effects in some 4D theaters, but now with 5D theaters, audiences can experience new Unique features, touch and feel effects such asreal smoke, water, snow, bubbles, smell, lightning, leg touch,camera system and more. When the audience is watching amovie, the seats and environmental effects will change into corresponding actions according to the development of the movie,allowing the audience to experience an immersive viewing experience.