Maintenance Tips for Sports Simulation Equipment

- Keeping Your Sports Simulation Systems Game-Ready

- Why proactive maintenance matters for sports simulation

- Environmental controls: the foundation of longevity for sports simulation

- Daily and weekly maintenance checklist for sports simulation (: maintenance service)

- Cleaning and disinfection—what to use and what to avoid (: replacement parts & consumables)

- Calibration best practices for accurate tracking and gameplay

- Spare parts strategy and inventory control (: parts provider)

- When to choose preventive, predictive, or reactive approaches (: maintenance contracts)

- Troubleshooting common issues and rapid fixes

- KPIs and metrics to track the health of your sports simulation assets

- Safety, compliance, and warranties

- How JAMMA Amusement supports long-term reliability of sports simulation attractions

- Practical service contract considerations when partnering with a supplier

- Case example: reducing downtime for a multi-simulator venue

- Budgeting for maintenance: rule-of-thumb numbers

- FAQ — Maintenance Tips for Sports Simulation Equipment

- 1. How often should I calibrate my sports simulator?

- 2. What cleaning products are safe for VR headsets and camera lenses?

- 3. Which parts should I keep as spares on-site?

- 4. How can I measure if maintenance is effective?

- 5. Is predictive maintenance worth the cost for a single-site operator?

- 6. Who should perform annual calibrations and inspections?

- Contact and next steps

- References

Keeping Your Sports Simulation Systems Game-Ready

Sports simulation systems are complex integrations of sensors, displays, projection systems, mechanical components, and software. Proper maintenance preserves gameplay quality, reduces downtime, and protects the substantial capital investment operators make in sports simulation attractions. This article provides pragmatic, field-tested maintenance tips for sports simulation equipment, including checklists, calibration guidance, environmental controls, spare-part strategies, and measurement-based KPIs to help venue managers, technicians, and buyers maximize uptime and ROI.

Why proactive maintenance matters for sports simulation

Sports simulation systems—golf simulators, batting cages with ball-tracking, AR/VR sports experiences—combine hardware and software complexity. Failures cause lost revenue, sour customer experiences, and sometimes safety risks. Proactive maintenance delivers measurable benefits: higher uptime, longer equipment life, lower emergency repair costs, and steady guest satisfaction. Operators typically see maintenance cost reductions of 20–40% when moving from reactive to preventive strategies (source: McKinsey analysis on predictive maintenance trends).

Environmental controls: the foundation of longevity for sports simulation

Environmental factors (temperature, humidity, dust, and vibration) are major determinants of electronic and mechanical lifespan. Best practices:

- Maintain stable ambient temperature: ideally 18–27°C (64–80°F). Rapid thermal cycling stresses components.

- Control relative humidity to 40–60% to avoid condensation on optics or corrosion on electronics.

- Use air filtration—fine-particle filters (MERV 8–13) for rooms with projectors and cameras; consider local dust shrouds for open PC/AV racks.

- Isolate equipment from heavy vibration (e.g., mechanical hitting areas) using dampers to protect internal mounts and sensors.

Data point: projector and camera performance degrade faster in dusty, high-humidity environments; manufacturer lamp and sensor lifespans are often quoted under controlled conditions (see projector and VR headset manufacturer guidance).

Daily and weekly maintenance checklist for sports simulation (: maintenance service)

Adopt a routine checklist your front-line staff can run each day before opening and weekly for deeper checks. The table below outlines a practical schedule.

| Interval | Task | Why it matters | Estimated time |

|---|---|---|---|

| Daily | Power-on diagnostics, quick visual inspection of screens, projectors, sensors, hitting mats, and safety barriers | Identifies immediate faults before guest use | 5–15 minutes |

| Daily | Clean high-touch surfaces and headset foam with manufacturer-approved wipes; microfiber-clean lenses | Hygiene and optics clarity; reduces wear | 10–20 minutes |

| Weekly | Vacuum and dust AV cabinets; inspect cable routing and connectors; check UPS/battery status | Prevents overheating and connection faults | 30–60 minutes |

| Monthly | Calibrate cameras/tracking systems; verify projector alignment and focus; firmware/software updates | Maintains tracking accuracy and image geometry | 1–3 hours |

| Quarterly | Full systems test, replace disposable components (e.g., headset face covers, foam inserts), lubricate mechanical parts | Preemptive replacement avoids in-session failures | 2–4 hours |

| Annually | Professional inspection and calibration by trained technician; review KPIs and spares inventory | Expert validation of long-term reliability | Half to full day |

Cleaning and disinfection—what to use and what to avoid (: replacement parts & consumables)

Cleaning practices must protect optical surfaces and electronic components. General recommendations:

- Use soft microfiber cloths for lenses and screens; avoid paper towels that scratch coatings.

- Use manufacturer-recommended cleaning solutions. For many VR headsets and optics, 70% isopropyl alcohol is acceptable on exterior plastic and removable facial interfaces but may damage headband materials or lens coatings—check the device manual first (example: headset vendor support pages).

- Never spray liquids directly onto components; apply to the cloth first.

- For mechanical parts (e.g., ball return ramps, batting cages), remove debris daily and use light machine oil or silicone lubricant where specified by manufacturer.

- Record consumable replacements (foam pads, face covers, projector air filters) to maintain hygiene and image quality.

Calibration best practices for accurate tracking and gameplay

Accurate calibration ensures scoring precision and a natural feel. Key steps:

- Follow vendor calibration routines for cameras and IR sensors after any significant repositioning.

- Use consistent lighting when calibrating—avoid direct sunlight on cameras or projected screens during calibration runs.

- For simulator mats and force sensors, use manufacturer calibration weights or certified tools at recommended intervals.

- Document calibration parameters and keep a change log to track drift and recurring offsets.

Spare parts strategy and inventory control (: parts provider)

Keeping critical spares on-site reduces MTTR (mean time to repair). Typical recommended inventory for a single-simulator installation:

- 1 spare projector lamp or an extra LED projector module (depending on model)

- 1 spare camera or sensor module for tracking systems

- Extra headsets or facial interfaces for VR systems

- Replacement drive belts, fuses, connectors, and a small electronics toolkit

- Consumables: filters, cleaning wipes, latex-free face covers

Use a simple inventory management system (spreadsheet or cloud tool) to log serial numbers, purchase dates, expected lifespans, and reorder triggers.

When to choose preventive, predictive, or reactive approaches (: maintenance contracts)

Comparison summary:

| Approach | Description | Typical cost profile | Best for |

|---|---|---|---|

| Reactive (fix when broken) | No scheduled maintenance; repairs on failure | Low short-term, high long-term; unpredictable downtime | Small operations with low utilization |

| Preventive (scheduled) | Regular inspections, cleaning, part replacement on schedule | Moderate predictable cost; reduces emergency repairs | Most venues (mid-to-high utilization) |

| Predictive (condition-based) | Use sensors/telemetry to predict faults before they occur | Higher upfront for monitoring; lowest long-term repair & downtime costs | Large-scale operators and multi-site deployments |

Real-world data from industrial maintenance studies indicate predictive strategies can reduce downtime and maintenance costs substantially; however, initial investment in telemetry (temperature, vibration, error logs) and analytics is required (source: McKinsey, predictive maintenance research).

Troubleshooting common issues and rapid fixes

Quick troubleshooting checklist when a simulator underperforms:

- Restart system and check software logs for errors—note timestamps and error codes.

- Check network connectivity and IP addresses for cloud-connected features.

- Inspect camera/sensor lenses for smudges; clean and retry.

- Confirm projector input selection and resolution settings; re-run auto-keystone if image misaligned.

- Swap suspect components (e.g., headset or camera) with a known-good spare to isolate faults.

KPIs and metrics to track the health of your sports simulation assets

Useful metrics to monitor monthly or quarterly:

- Uptime percentage (goal: >98% for commercial venues)

- Mean Time Between Failures (MTBF)

- Mean Time To Repair (MTTR)

- Maintenance cost per operating hour

- Customer-reported issues per 1,000 sessions

Track trends, not just single events—rising frequency of a specific fault indicates root-cause action (e.g., redesign of cabling path, improved shock mounting).

Safety, compliance, and warranties

Safety procedures are non-negotiable. Follow electrical safety standards, keep ingress protection ratings in mind for outdoor installations, and preserve warranty coverage by using authorized service partners for significant repairs. Record all service actions and maintain a calibration log; many warranties require proof of regular maintenance.

How JAMMA Amusement supports long-term reliability of sports simulation attractions

JAMMA Amusement was established in 2009 in Guangzhou and brings 15 years of industry experience focused on high-value, one-stop amusement project solutions. Our offerings include VR games, AR sports simulators, AR interactive projection games, 5D cinema, arcade games, and outdoor playground equipment. For sports simulation operators, JAMMA provides:

- Industry-tailored hardware engineered for commercial use—robust sensors, commercial-grade projectors, and easily serviceable mechanical modules.

- Comprehensive spare parts and consumables packages optimized for uptime (replacement mats, sensor modules, filters, headset interfaces).

- Technical services: installation, on-site calibration, training for local staff, and preventive maintenance contracts.

- A responsive international sales team and an industry-leading technical R&D group that continuously updates systems to current technology standards.

Our manufacturing and after-sales teams are experienced in delivering high-quality products and technical support to venues worldwide. We are committed to becoming a leading global provider of amusement equipment and park solutions. JAMMA’s core products and advantages: Sports Simulators, Interactive Projection Games, Immersive Attractions, and VR Games—engineered for durability, ease of maintenance, and strong commercial performance. Learn more at https://www.jammapark.com/.

Practical service contract considerations when partnering with a supplier

When evaluating maintenance or service contracts from a supplier like JAMMA or others, consider these points:

- Service level agreements (SLAs) with guaranteed response and repair windows.

- Clear scope for preventive checks and included consumables.

- Availability and shipping time for critical spares in your region.

- Remote diagnostic capabilities and software update policies.

- Training for local staff to perform daily and weekly maintenance tasks.

Case example: reducing downtime for a multi-simulator venue

In one typical project, moving from reactive fixes to a preventive schedule plus a local spare-part kit reduced emergency repairs by 60% and improved uptime to 99% over a 12‑month period. The venue tracked MTTR and found average repair time dropped from 8 hours to under 2 hours after technicians received targeted training and spare modules were stocked locally.

Budgeting for maintenance: rule-of-thumb numbers

While exact figures vary, a practical budgeting framework is:

- Preventive maintenance budget: 5–10% of equipment purchase price per year.

- Spare parts reserve: 5–15% of initial equipment value held as inventory.

- Upgrade/predictive monitoring investment (optional): 10–25% upfront for analytics hardware/software if multi-site scale justifies it.

These are rule-of-thumb estimates; develop a tailored plan based on utilization, local environment, and revenue targets.

FAQ — Maintenance Tips for Sports Simulation Equipment

1. How often should I calibrate my sports simulator?

Calibrate cameras and tracking systems monthly under normal use. If the simulator is used intensively (many sessions per day) or after any hardware movement, recalibrate immediately. Keep a log of calibration results to detect drift.

2. What cleaning products are safe for VR headsets and camera lenses?

Use microfiber cloths and manufacturer-approved cleaning solutions. Many vendors permit 70% isopropyl alcohol for exterior plastics and replaceable face pads, but avoid alcohol directly on lenses—use lens cleaner recommended by the headset maker. Always check the device manual for model-specific instructions.

3. Which parts should I keep as spares on-site?

Maintain spares for high-failure or long-lead items: a spare camera/sensor module, an extra headset or facial interface, projector lamp/module, common connectors/fuses, and consumables (filters, wipes, pads).

4. How can I measure if maintenance is effective?

Track KPIs: uptime percentage, MTBF, MTTR, maintenance cost per operating hour, and customer-reported issues per 1,000 sessions. Improvements in these numbers indicate better maintenance efficacy.

5. Is predictive maintenance worth the cost for a single-site operator?

Predictive maintenance pays when utilization and revenue justify the upfront investment. For single-site operators with moderate traffic, a strong preventive program plus local spares is often the most cost-effective approach. Predictive monitoring becomes attractive for multi-site operators or very high-use venues.

6. Who should perform annual calibrations and inspections?

Annual calibrations should be done by trained technicians—either certified in-house staff or authorized service providers from the equipment manufacturer or a trusted partner like JAMMA Amusement.

Contact and next steps

If you operate sports simulation attractions and want a maintenance plan tailored to your venue (or need reliable spare parts and technical service), JAMMA Amusement can help. With 15 years in the amusement industry and a full product line including Sports Simulators, Interactive Projection Games, Immersive Attractions, and VR Games, we provide turnkey solutions, spare-part programs, and professional maintenance support. Visit our website: https://www.jammapark.com/ or contact our international sales team to discuss a site assessment, preventive maintenance contract, or parts package tailored to your needs.

References

- McKinsey & Company — The case for predictive maintenance (industry analysis). https://www.mckinsey.com/ (accessed 2025-11-30).

- IAAPA (International Association of Amusement Parks and Attractions) — industry resources and best practices. https://www.iaapa.org/ (accessed 2025-11-30).

- Projector manufacturer support and lamp life specifications (example: Epson projector support pages). https://www.epson.com/support/ (accessed 2025-11-30).

- VR headset vendor cleaning and maintenance pages (example: Meta and HTC support guidance). https://support.meta.com/ and https://www.vive.com/support/ (accessed 2025-11-30).

- Occupational Safety and Health Administration (OSHA) — electrical safety and workplace safety guidance. https://www.osha.gov/ (accessed 2025-11-30).

- JAMMA Amusement official website — product and company information. https://www.jammapark.com/ (accessed 2025-11-30).

Top 5 interactive basketball game Company List and Products Compared in Europe

Why choose JAMMA as your 4d moving theatre manufacturer in Europe

Best led interactive game floor manufacturers and supplier brands in us

OEM/ODM interactive dance floor led manufacturers Manufacturers and Suppliers

Product details

What is the difference between 5D and 3D?

The visual of 5D cinema is the same as that of 3D, compared to 3D, it adds motion simulation and special effects, which are not available in 3D.

Are glasses required to see a 5D film?

Audience needs to wear 3D glasses while watching movie, but not VR glasses.

Standard and other

Do you offer a customized service?

We can provide logo customization service for all of our products. For certain products, we can also support customization of sizes and game content. If you have any product customization requirements, please contact us and we will confirm the details with you.

How long is the warranty period?

Our products have a one-year warranty period. During the warranty period, if there are any issues with the product that are not caused by human error, we can replace the parts for you free of charge. If the problems are caused by improper use, you will need to purchase the parts and bear the shipping costs yourself.

Do you offer installation services?

Our professional implementation team can provide equipment installation and debugging services to ensure smooth operation. Our installation services is chargeable and you can contact us in to inquire about the service fees.

Hottest activated LED dance grid tiles floor touch games

Super Grid is an immersive sports game that combines sports and technology. It integrates interactive LED lights and sensors through innovative software design, creating a fun gaming experience.

Top Indoor Tennis Racketball Training Simulator Dual Player Games

Interactive somatosensory fitness game

Combine traditional tennis sports with advanced 3D digital technology to bring customers an immersive tennis training experience

COMBINE TRADITIONAL TENNIS SPORTS WITH ADVANCED 3D DIGITAL TECHNOLOGY TO BRING CUSTOMERS AN IMMERSIVE TENNIS TRAINING EXPERIENCE INDOOR AND TENNIS EXPERIENCE HALL

Super Grid Interactive LED Floor Activate Game Team Play

Super Grid is an immersive sports game that combines sports and technology. It integrates interactive LED lights and sensors through innovative software design, creating a fun gaming experience.

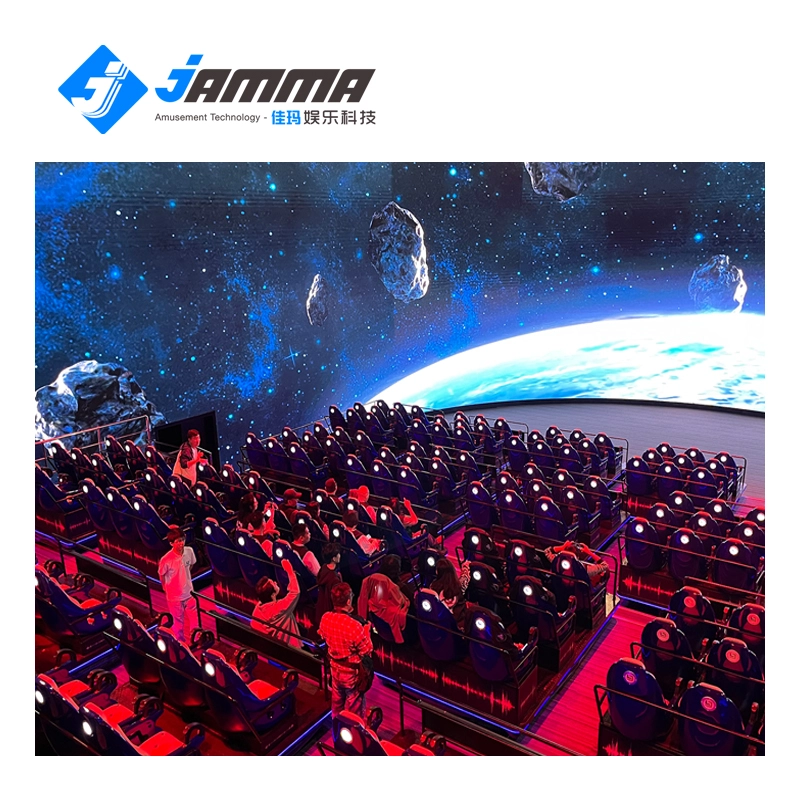

Immersive 5D/7D/9D cinema dynamic visual experience room

Compared with other types of theaters, 5D/7D/9D cinema have high technical content, prominent themes, and have a strong impact on the characteristics of the picture. With the increasing demand in the entertainment market and the continuous development of video entertainment technology, in the past, audiences would experience vibration, drop, rain, scratches and other effects in some 4D theaters, but now with 5D theaters, audiences can experience new Unique features, touch and feel effects such asreal smoke, water, snow, bubbles, smell, lightning, leg touch,camera system and more. When the audience is watching amovie, the seats and environmental effects will change into corresponding actions according to the development of the movie,allowing the audience to experience an immersive viewing experience.